April 2, 2025

Organized by IERE

Moderator

Jayant SARLASHKAR

SwRI

US

Lecturers

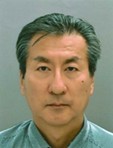

Jayant SARLASHKAR

SwRI

US

Contact: Jayant[dot]sarlashkar[at]swri[dot]org

Abstract:

Grid modernization has become a new refrain in the electric utility industry. The electric grid is aging, and its modernization is imperative. One of the unique challenges of the electric grid is the need to constantly match supply to demand lest the grid become unstable. A large portion of the electric supply is relatively fixed over a short duration. The demand, however, can fluctuate unpredictably. Battery storage, as a multi-time-scale source and energy sink, is beginning to revolutionize electric distribution. Value-stacking – using battery energy storage for a variety of grid services – is becoming popular. Services such as solar shifting, arbitrage, frequency regulations, voltage support, etc., subject the battery to large swings in state-of-charge (nearly full to nearly empty), power levels, and event duration (seconds to hours). However, longevity and safety of batteries under such mixed operation is unclear, which was the subject of this joint industry project (JIP). Performance degradation and safety of batteries under mixed grid duty are important considerations from life-cycle cost and societal perspectives. The JIP conducted by the Southwest Research Institute had five members, which included utilities and research organizations around the world. This presentation provides an overview of the four main accomplishments of the JIP – (1) statistical characterization of field data, (2) development of an extended single particle model with temperature (SPMeT) of a lithium-ion cell, (3) development of an in-situ test to adjust parameters of this model, (4) implementation and demonstration on the research BESS at SwRI.

Biography:

Jayant Sarlashkar is an Institute Engineer at the Southwest Research Institute (SwRI) in San Antonio, TX, USA. Over the last nearly 30 years, he has focused on improving efficiency of and reducing emissions from the transportation industry. He is in-charge of the research BESS and the research solar field at SwRI. He was the principal investigator of the joint industry program SwRI and IERE conducted on BESS in electric grid. He has a general interest in control systems and optimization.

TAKAHASHI Kazunari

Battery Engineer, Toshiba Energy Systems & Solutions Corporation

Japan

Contact: https://www.global.toshiba/ww/products-solutions/renewable-energy/contact.html/

Abstract:

Toshiba ESS has developed and provides a storage battery system that uses lithium-ion batteries as one of the technologies for grid stabilization and an energy management system (EMS) for microgrids to contribute to the promotion of renewable energy.

Renewable energy fluctuates depending on the natural environment, so such grid stabilization technology is essential to use it as a stable power source.

In recent years, this technology has been adopted mainly in island countries where the ratio of renewable energy is increasing. By applying this technology, we will promote the introduction of renewable energy and reduce CO2 emissions by reducing fuel for generators at power plants, thereby contributing to the improvement of environmental issues such as global warming.

In this session, we will introduce the technology and application examples of the storage battery system and EMS equipped with lithium-ion batteries (SCiBTM) developed by Toshiba ESS.

Biography:

In 2022, I joined Toshiba ESS in the Energy IoT Promotion Department of the Energy Aggregation Division and participated in various battery storage system projects as a battery storage system engineer. In recent years, we have been involved in the relocation of the battery storage system on Nii-jima as part of a project to connect Japan's first PCS with pseudo-inertia function to an actual grid. Overseas, I oversee a large-scale battery storage system for suppressing fluctuations in renewable energy in Cuba. I am currently in charge of adding functions such as autonomous operation in Phase 2 and is promoting battery storage system projects both in Japan and overseas.

KITOH Kenshin

General Manager, Department Energy Storage Division, NGK INSULATORS, LTD.

Japan

Contact: kitoh[at]ngk[dot]co[dot]jp

Abstract:

Achieving carbon neutrality requires the introduction of substantial renewable energy sources. However, a major challenge lies in how to stably supply these energy sources, which fluctuate due to weather conditions. While pumped-storage hydroelectricity is used to balance electricity demand and supply, constructing new facilities is difficult. Therefore, adjustments are being attempted with large grid batteries and demand response at consumer sites. This lecture introduces the technology of sodium-sulfur (NAS) batteries and examples of their use in contributing to CO2 reduction.

Biography:

In April 1989, Kenshin Kitoh joined NGK Insulators, Ltd., where he was assigned to the Research and Development Division, focusing on fuel cells and batteries. From April 2007, he worked in the NOx Sensor Division within the Ceramics Business Group. In April 2011, he returned to the Research and Development Division, continuing his work on batteries. By April 2020, he had become a Senior Manager in the Department Energy Storage Division, and now he is a sales engineer dedicated to enhancing the NAS battery business. Throughout his career, Kenshin Kitoh has devoted himself to the field of electrochemistry and batteries.

SHIBATA Toshikazu

SVP, Chief Engineer of Energy Storage System

Sumitomo Electric U.S.A., Inc.

Contact: tshibata[at]Sumitomo[dot]com

Abstract:

In pursuit of a decarbonized society, the deployment of renewable energy sources is accelerating worldwide. To efficiently utilize these energy sources, energy storage systems play a crucial role.Flow batteries are a type of rechargeable battery that stores energy in liquid electrolytes contained in external tanks. During operation, these electrolytes are pumped through electrochemical cells, enabling charge and discharge reactions. Unlike conventional batteries, flow batteries allow energy capacity to be scaled independently by increasing tank size, making them well-suited for long-duration energy storage.Key advantages include a long lifespan due to minimal electrode degradation, low fire risk as they use non-flammable electrolytes, and environmental sustainability with reusable electrolytes and recyclable materials. Their ability to provide long-duration energy storage makes them ideal for stabilizing renewable energy sources and supporting grid reliability.In this web session, I will introduce the principles, characteristics, and recent deployment cases of flow battery technology.

Biography:

Toshikazu Shibata received his M.S. degree in Electrical Engineering from Kyoto University, Japan, in 1992. He joined Sumitomo Electric Industries the same year and initially focused on the research and development of large-capacity power cables, including superconducting power cables and DC-XLPE power cables. Since 2003, he has been actively involved in the design and development of flow battery systems, leading numerous flow battery system projects as a project manager. He is also a member of the IEC TC21/JWG7 committee, contributing to the development of international standards for stationary flow battery systems.

Q&A—Typical QuestionsThe day was filled with many questions and a lively Q&A session.

(L-1) Estimating and Managing Degradation of Li-Ion BESS Under Value-Stacked Duty Cycles in Electric Grid

(L-2) Battery Energy Storage Systems for Power Grids(SCiBTM)

(L-3) Stabilizing Renewable Energy Supply with Sodium-Sulfur Batteries: A Path to Carbon Neutrality

(L-4) Advancements & Deployment of Flow Battery System Technology